Introduction

The first issue to look at is the significance of flue gas desulfurization (FGD) as a technology for removing sulfur dioxide (SO2) from industrial processes such as coal fired power plants. With environmental regulations becoming stricter and advances in technology, the future of FGD is promising as challenging towards innovation for more efficient sustainable cost-effective solutions. In other words, this article discusses the present situation of moving technology, some new technologies that are nearing maturity and future trends that will dictate the momentum in this discipline.

The Status Quo Of FGD Technology

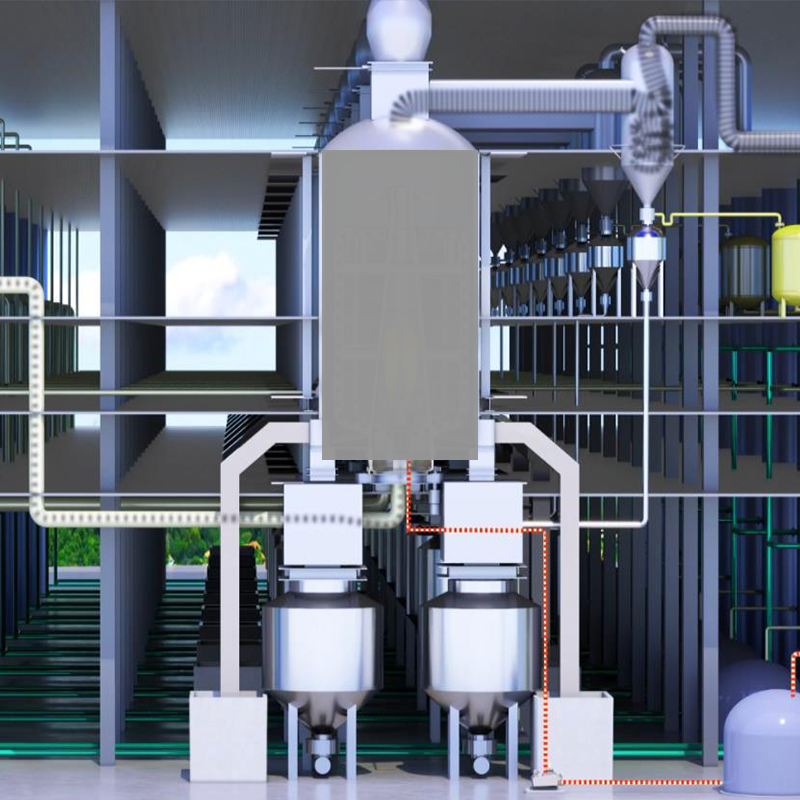

FGD methods are commonly divided into wet, dry, and semi-dry processes. Dry FGD uses no water, whereas wet FGD which is the most prevalent type of method used has an alkaline slurry that absorbs SO2 in an absorber (usually a spray tower). Dry and semi-dry FGD methods, on the other hand, use a solid sorbent such as lime or limestone that reacts with SO2 to produce a dry by-product. Each of the three methods has its own pros and cons, including high efficiency in wet FGD but liquid waste production, as well as a more environmentally-friendly nature with dry/semi-dry methods but is known to be less efficient.

Innovations in FGD Technology

Recent info: in flue-gas desulfurization technology Advances in mass transfer technologies and process parameters have led to higher sorbent utilization efficiency, with faster rates of desulfurization. In this respect, the development of new sorbents and materials, such as waste or nanomaterials can improve the sustainability and efficiency of FGD.

The Other new approach is the combined use of FGD with other processes for pollution control including simultaneous removal SO2 as well as certain other pollutants. It also provides the sustainable disposal pathway for by-products of FGD in the type of cement production.

Sustainable FGD Technologies

The drive toward zero liquid discharge (ZLD) in FGD systems has spurred the development of creative water treatment and reuse strategies. The use of advanced separation technologies has allowed for less wastewater produced, further helping minimize the environmental impact of FGD processes.

Energy efficiency improvements in FGD have been a major concern as well. FGD systems used for desulfurization should minimize energy consumption and waste heat recovery is a way to make FGD more sustainable.

Treaties and FGDs

Therefore, FGD innovation is driven by global environmental agreements. The Kyoto Protocol and Paris Agreement have stimulated development of more effective FGD technologies required to respond to the impact on reducing SO2 emissions.

Beyond regional borders, international collaboration is also needed to drive FGD technology forward. The sharing of best practices and technologies between the countries and joint research & development together can bring in game changing advancements towards FGD.

Future Trends in FGD

With current research development, the feature of FGD is expected to be more efficiency and smaller scale systems. The use of the dry and semi-dry FGD methods is also expected to rise due to their lower environmental impacts.

There is one exciting trend of artificial intelligence and automation in FGD. FGD process parameters optimization can be performed using AI and automation can increase the safety and reliability in the operation of FGD.

Conclusion

It is, therefore, a highly innovative and trendsetting area for the future of flue gas desulfurization. Further research and development into FGD is needed to meet the far-reaching requirement for cleaner, more efficient emission control technology. The necessity for and global cooperation related to solving the problems of sulfur-emission control: Advances in FGD technology; With the whole world shifting towards cleaner energy and more stringent emissions rules being enforced, FGD will be a key player in saving the environment and human health.