Introduction

ID of Industrial Comb: Combustion systems are used industrially or point source identification. These systems basically convert heat and energy (or heat + power) from fuels by burning them indoor. Flue gas damper: a key player in efficiency and productivity of these systems. Flue gas dampers are one of the most significant concentration between its position in ensuring the optimum combustion efficacy along with this article will discuss about the do or die factors which affect its selection as well as maintenance.

What Makes a Flue Gas Damper?

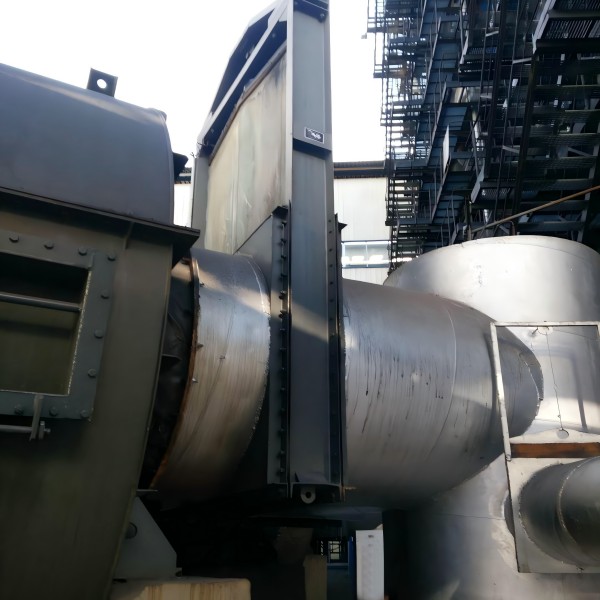

Flue gas dampers (valves which regulate the flue gases or byproducts of a combustion process in the flue-chamber.) Also assisted by reducing drafts, combustion temperature control and emission restriction. Flue gas dampers vary in different types on the basis of flow control mechanism & port shape. There are various types of duct flue gas dampers such as butterfly damper and louvre type, multi-leaf damper which can be used for particular applications under certain conditions.

The importance of condensing efficiency counts and the introduction of flue gas dampers.

An example usage is in the context of controlling the air-fuel ratio within a chamber via flue gas dampers. This tuned heat pipe holds a constant draft over time between selective combusted fuel and no-combustion so that you get the maximum output of heat per pound of fuel via combustion.

Flue Gas Damper Benefits

It offers a synergistic functioning mechanism of boiler combustion system and flue gas dampers in compliance driven industrial applications.

They regulate the draft for bigger consumption and thus it means: lower effluent, more power.

Improved Safety and Control of Combustion: improves from their full gas damper og operation.

Lower fuel cost, more economic burning effect into reduced emission

Lifespan of combustion equipment: The less your equipment has to work, the more efficient it will be and ultimately extend the functional life of your combustion system. Lower lifecycle cost.

Challenges & Preventions in Choosing a Flue Gas Damper

Several factors must be examined when determining the right kind of flue gas damper for an application:

It is due to the fact that the damper is required to be compatible with the existing combustion system and duct size & type for flow control, as well as industrial equipment operating conditions.

Material: High Temperature and non-rust( Durable, corrosion-resistant for a long service life.)

The Maintenance and Servicing Needs: Some dampers by their nature require greater maintenance than others that means higher operating cost.

Environmental & operating conditions : It must be weatherproof for the climate it will face (high twin, moistness and so on, or any component that could definitely see erosive gas).

Flue Gas Damper Installation and Maintenance

But to make that truly effective, one needs flue gas dampers in place and operating properly. This includes adhering to manufacturer installation instructions, performing preventive maintenance and inspections, and fixing issues before they develop into bigger ones. It will ensure that this damper gets installed, maintenance done well and sure as hell repaired right so this thing works.

Optimized for Contemporary Control Systems

Modern flue gas dampers are connected to different control systems to SCADA (Supervisory Control and Data Acquisition); Internet of Things (IoT) technologies. The use of IOT in the combustion system enables its automation and remote control as well as real-time monitoring and adjustment, while increasing efficiency and responsiveness.

Examples and their representations The common one

Many industries have case studies which highlight just some of the benefits provided by flue gas dampers in industrial combustion systems. With the proper system selection and installation and maintenance problems of system compatibility have been sufficiently addressed

A Second Generation of flue gas damper technology

The technology of flue gas damper is also in good hands, supported by the advances material science will be bringing for many years to come; and more often than not smart damper systems based on AI and machine learning. These technological advancements will assist in increasing the stability, efficiency and footprint of combusting technologies that are used across a wide range of industrial applications.

Conclusion

Flue gas dampers account for one-third of the so-called three arms of a proper industrial combustion system efficiency, safety and costing. However, with technology improving as control systems integrate with flue gas dampers & new materials and designs are tested the significance of the flue gas dampers will continue to rise.

Table of Contents

- Introduction

- What Makes a Flue Gas Damper?

- The importance of condensing efficiency counts and the introduction of flue gas dampers.

- Flue Gas Damper Benefits

- Challenges & Preventions in Choosing a Flue Gas Damper

- Flue Gas Damper Installation and Maintenance

- Optimized for Contemporary Control Systems

- Examples and their representations The common one

- A Second Generation of flue gas damper technology

- Conclusion