Introduction

Now, remember that every year millions of tyres are reaching the end of their life cycle and so it is a great environmental threat by any means. Same is the Used Car Tires — they lead waste pollution as well, in illegal dumping or fire. It has stayed a reality through reusing of idea by means of pyrolysis to convert waste tires to advance through step at step.

Understanding Pyrolysis

Pyrolysis is the thermal decomposition of organic materials (in the absence or to a limited incomplete combustion in inert atmosphere), at elevated temperatures. Pyrolysis is a process that involves heating of the tire in order to break down different constituents of waste tire for recycling into oil gas char metal steel etc. This approach differs from other recycling methods that tends to circulate and regenerate in less sustainable form whilst imposing larger carbon footprints spiral of enrichment for the new at the expense of waste that have need to treat, so it is about recovery of original material as-it-is.

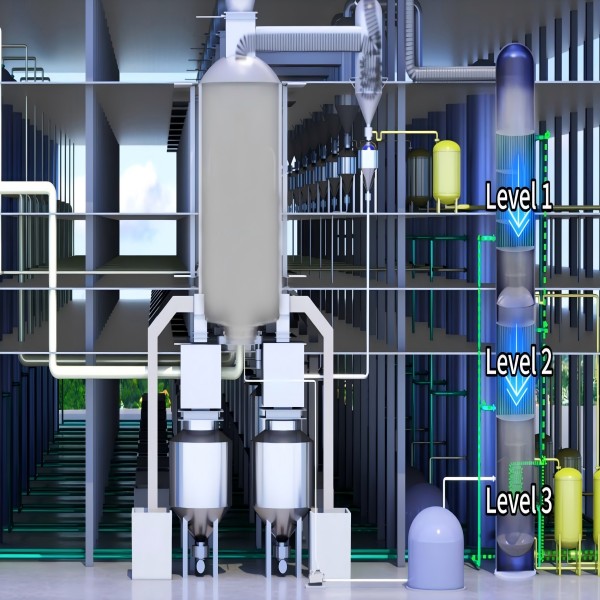

The Process of Tire Pyrolysis

Before the waste tires can be put into the tire pyrolysis process, they must go through pre-treatment — to remove non-tire materials and shred them into smaller sizes. The tires are next placed into a reactor (the Pyrolysis component of tire recycling) where they enter a meet high-temperature heating, leading the tire to decompose into its building blocks. Different products such as oil and gas, char and steel are collected.

Tyre Pyrolysis Products

Applications: There are several uses of tyre pyrolysis products;

Pyrolysis Oils: The oil resulting from pyrolysis can then be distilled and subsequently used as a fuel or in other industrial process.

Gas: The gas is a pyrolisis product and can be utilized as fuel for the pyrolysis plant itself reducing or eliminating commercial energy input

Steel : The metal that can be removed from tires can use to create fresh steel goods

The advantage of scavenging the environment by tire pyrolysis

Thus, pyrolysis is a green process. Tire pyrolysis contributes to addressing the global environmental challenge of contradictory and hazardous tire waste by converting used tires away from landfilling, preventing complications caused by illegal dumping or incineration, As a circular model as well as we recycle tirers into products and we ARE quite AVOID virgin material.

Tire pyrolysis, however, only if the math works out

Thus, the capital and operating costs of a tire pyrolysis plant, the selling prices to be fetched in product markets as well as government incentives determine its profitability. We could sell the oil, gas, char and even steel recovered at the pyrolysis plant — even if only for enough to cover Burchy Bills. More carrots from the government for better recycling and other forms of waste reduction will merely pour gasoline on the flame of a pyrolysis economy.

Absence of operational and technical boundaries

Although there are numerous advantages for the thermal conversion of waste tires, this technology is also faced with very serious technical and operational issues due to undesirable products which affect directly the feed material etc. leading in turn to possibly lower quality waste accumulation over the time [6]. In addition, it will have to address the environmental quotas it meets (or not), along with GHGs from the pilot and dumps and car safety concerns. This means new technology of advanced pyrolysis as well as strict operation procedures at the first site must be modified to solve these challenges.

Examples and Testimonials

The existing tire pyrolysis plants throughout the world prove that this technology is a part of the solution. Also, through these plants they not only got jobs and economic activity for their local communities – but they brought environmental advantages by stopping waste tires from polluting the environment as pollutants and more environmentally benign non-renewable resources dead at end-of-life.

Tire Pyrolysis Process Trends and Technology Developments

Nevertheless, tire pyrolysis is still promising because the majority of tire pyrolysis technologies are developed sustainably and economically feasible. Such technology improvements (for example, improved pyrolysis reactors spent tyre with better recovery) will make shredder tyre this thick recycling process more favourable in the future.

Conclusion

In this, a material conversion of old tire load moisture-content rich material in to very precious end-products 'is the waste factor. In this way, it solves the possible environmental danger created by waste tires and employs you via processing of, oil plant, gas carbon black & steel with pyrolysis. Thus, considering the rapid advancements from R&I pyrolysis products development perspective such as, sustainable materials, and equally evolving technologies-perhaps creating winning combination of both processes (pyrolysis & Gov) would make it to be an essential recycling process for other non-whole rejected leather waste or tires particularly targeting such high-value resource and cleaning up contaminated environmental & circular economy making it pollution-free cycle.

Table of Contents

- Introduction

- Understanding Pyrolysis

- The Process of Tire Pyrolysis

- Tyre Pyrolysis Products

- The advantage of scavenging the environment by tire pyrolysis

- Tire pyrolysis, however, only if the math works out

- Absence of operational and technical boundaries

- Examples and Testimonials

- Tire Pyrolysis Process Trends and Technology Developments

- Conclusion